How Does RFID Work in Retail?

Retailers such as Macy’s, Target, Walmart, Kohls, Nordstrom and several more are currently relying on RFID technology to ensure end-to-end supply chain efficiency. But, how exactly do retailers use RFID? In some cases, retailers apply RFID tags to their merchandise at the item-level. This means that certain products have RFID directly affixed to themselves.

Retailers often affix RFID tags directly to the following kinds of inventory:

Jewelry

Handbags

Makeup kits

Luxury brand shoes

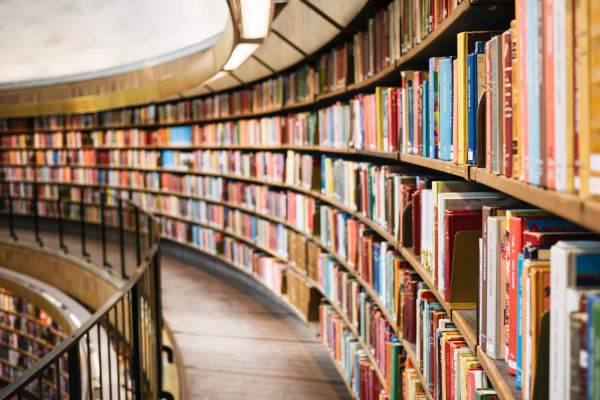

RFID is commonly deployed in retail supply chains to improve inventory accuracy. From initial inbound shipments all the way to final sale, retailers can track their goods thanks to RFID. This allows for optimal inventory visibility which makes modern retailing easier. With more accurate inventory, retailers can cater to popular shopping trends such as BOPIS (buy online, pickup in store). Major retailers may require vendors to tag their own goods and shipments as well. This is known as a RFID tag mandate. Retailers provide vendors with guidelines and expectations for tagging merchandise. Vendors and manufacturers will then be expected to adhere to the mandate. Failure to tag items according to the retailer’s mandate can often lead to financial penalties, chargebacks on merchandise, or a dissolution of the vendor/retailer partnership altogether.

What Are the Advantages of RFID Tagging in Retail?

RFID tags are often compared to barcodes since the tags will replace barcode scanning during inventory counting and inbound/outbound shipping and receiving. When comparing RFID to barcodes, RFID offers several major advantages for both retailers and suppliers.

1.Faster Item Counting – In a matter of seconds, entire sections of RFID tagged inventory can be scanned. This is far more efficient and accurate than having to scan barcodes one at a time.

2.Larger Data Storage – Standard 1D barcodes can store 85 characters. RFID tags on the other hand can store much more data. Alien’s Higgs 3 chip, for example, has a memory of 512 bits.

3.Data Variety – Unlike barcodes, RFID tags can be built with sensors that can capture specific information. RFID tags with sensors can sense movement, temperature, humidity, or sudden falls.

4.Durability – Barcodes have a tendency to disintegrate or peel off depending on how they are created and handled. RFID tags on the other hand can be ruggedized in order to handle harsh environments.

How does RFID help in apparel inventory management?

RFID and apparel are a perfect fit for many reasons. The biggest way RFID can help is by ensuring the most accurate apparel inventory numbers. In today’s omnichannel retail environment, it is vital for retailers to have accurate inventory data. Using RFID, retail employees can quickly scan inventory with a RFID reader and get highly accurate inventory counts in seconds. With more accurate inventory information, retailers can know when stock levels are low in a timely manner. That way, retailers can know when to order more inventory and avoid items going out-of-stock.

For higher value, apparel RFID can assist in loss prevention as well. Once inventory is tagged, employees or loss prevention specialists can be alerted when unauthorized movement of inventory occurs.

In some environments, simply locating inventory can be a challenge. Wedding dress shops, for example, have unique inventory needs that can be addressed with RFID. The location of a specific dress can be identified with an RFID reader that has a built-in geiger counter that can alert the employee when they are in close proximity. An RFID software application can also be used that can display the dress’ location via a floor map.